Splice Inspection and Service

Where bolt-style fasteners are used, it is important that the plates be kept properly tightened. The most practical way to achieve this is to tighten the bolts so that the rubber behind the plate slightly wells. Care must be taken not to over-tighten fasteners or “bury” the plates into the belt cover, as this could cause damage to the plies of the belting. Manufacturers generally suggest retightening the fasteners after the first few hours of operation, again after the first few days of operation, and then at intervals of two or three months of operation.

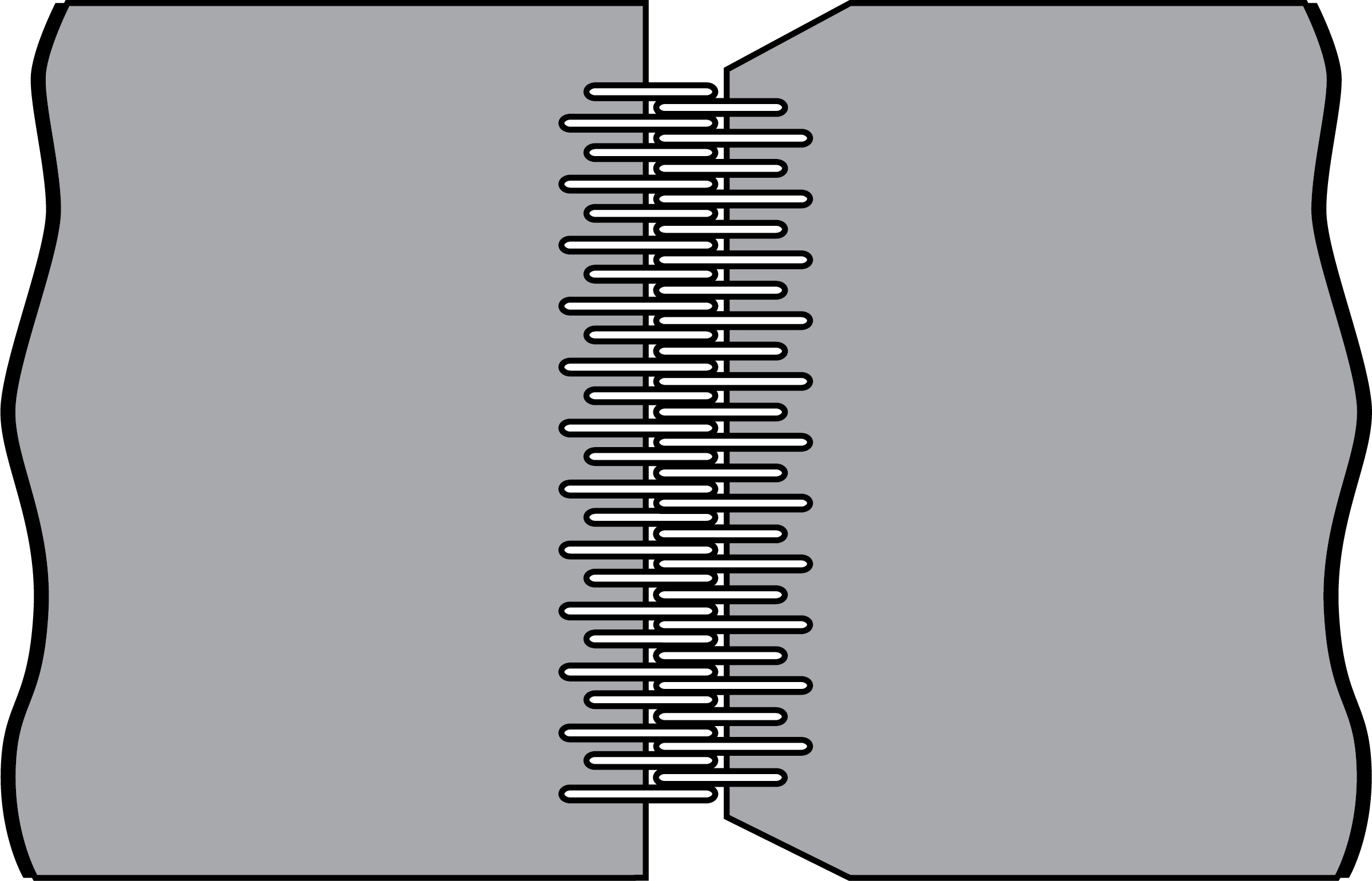

Splices should normally be inspected on a weekly basis, with replacement of any fasteners that look worn, watching for crosswise breaks on the back of fasteners, and checking for fastener pullout.

Splice-Monitoring Systems

Newer technologies are now available which allow the remote evaluation of splices by measuring any elongation of the splice. These systems are based on the principle that the lengthening of a splice is an indication of an impending failure. The system is installed on vulcanized belts by placing small magnetic targets into the belting at a set distance on either side of the splices; if the belt has mechanical fasteners in place, the system can use those as the targets. The system will monitor the distance between the paired targets each time a splice passes the scanner. This distance is measured, and if a splice falls outside the set limits, the monitoring system will shut down the belt or alert plant personnel to check the problem in addition the system can help identify if a clip has suffered severe damage and must be replaced.

The Importance of the Splice

Whether it is vulcanized or uses mechanical fasteners, a properly designed, well applied and maintained splice is critical to the success of a belt conveyor’s operations. Improper application of a splice will shorten the life of the belt and interfere with the conveyor’s operating schedule and efficiency. Care in applying the proper splice in the correct fashion will provide benefits for the entire plant. In other words of an old axiom: “If you don’t have the time to do it right, how are you going to find the time to do it over?”

See Also: Notching the Trailing Side of a Conveyor Belt Splice Part 1 | Part 2.

Leave Comment