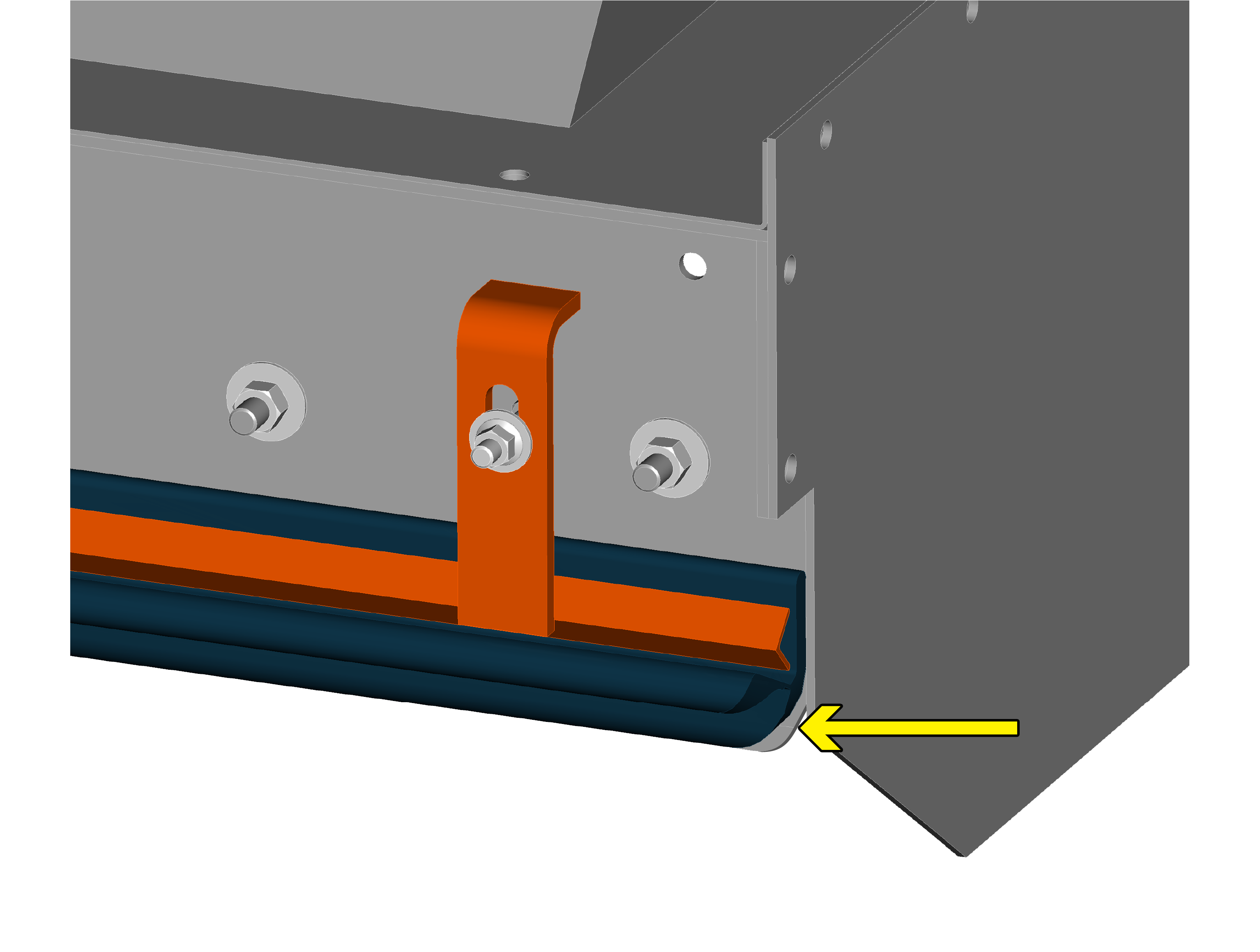

When specifying a skirt-sealing system, it is wise to consider its mechanism for adjusting and replacing the wearable rubber. As the conveyor runs, the heat generated by the friction of the belt against the skirting seal combines with the abrasive nature of the material fines to erode the sealing strip. To counter this wear, the sealing strip must periodically be adjusted down against the belt.

Applying too much downward pressure to the sealing system leads to additional power requirements to move the belt—it also leads to extra wear in both the belt and the seal.

If the procedures for the service of skirting rubber are cumbersome or complicated, three detrimental consequences are likely:

-

No adjustment

Adjustment does not happen at all, so the skirting strips wear, gaps open, and leakage resumes. -

Infrequent adjustment

Adjustment is made too infrequently, so spillage occurs intermittently. -

Over-adjustment

The maintenance person or conveyor operator, to compensate for not making regular adjustments, will over-adjust the seal. Applying too much force down onto the belt risks damaging the belt or catching a splice and ripping out the entire section of sealing strip.

To prevent these problems, skirtboard seal maintenance procedures should be as free of complications, tools, and downtime as possible.

Sealing systems that rest gently on the belt, using little more than the pressure of their own weight or the tension built into the design, can minimize the need for maintenance adjustment.

Some multiple-layer sealing systems provide a self-adjusting function, as the elastomeric memory maintains the sealing pressure. As the legs of the secondary strip wear, the natural resilience of the elastomer strip keeps it down on the belt, maintaining seal effectiveness.

Leave Comment