No Build-Up, No Damage:

View our full library of ON DEMAND webinars here.

Related Articles

Applied Vibration

Vibrators perform the same function as thumping on the outside of a bottle of ketchup: They reduce the cohesion between the material particles...

Rotary Vibrators

In contrast to linear vibrators, other vibrators create a vibratory force through the rotation of an eccentric weight...

6 "TIONS" of properly-sized and applied vibration

If I had a nickel for every time I’ve heard something like, “I’ve tried vibrators in the past but they don’t work,” I’d have enough nickels to help...

Hopper Damage and How to Prevent It!

A common concern that I occasionally hear is “I have material flow issues through my bin, hopper, or chute...

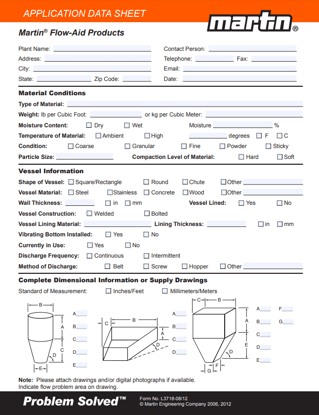

Want us to take a look?

Eliminate the need for guesswork, regulatory noncompliance, and internal resources spending time and money on maintenance.

Let us know if we can help overcome any material handling challenges you might be experiencing.

What to hear more from us?

Check out our blog or take a look at our newsletter for a quick and interesting read:

Stay Updated

Keep up with the latest posts and announcements on our social media platforms

/AirCannonsTransferPoint.png?width=675&height=450&name=AirCannonsTransferPoint.png)