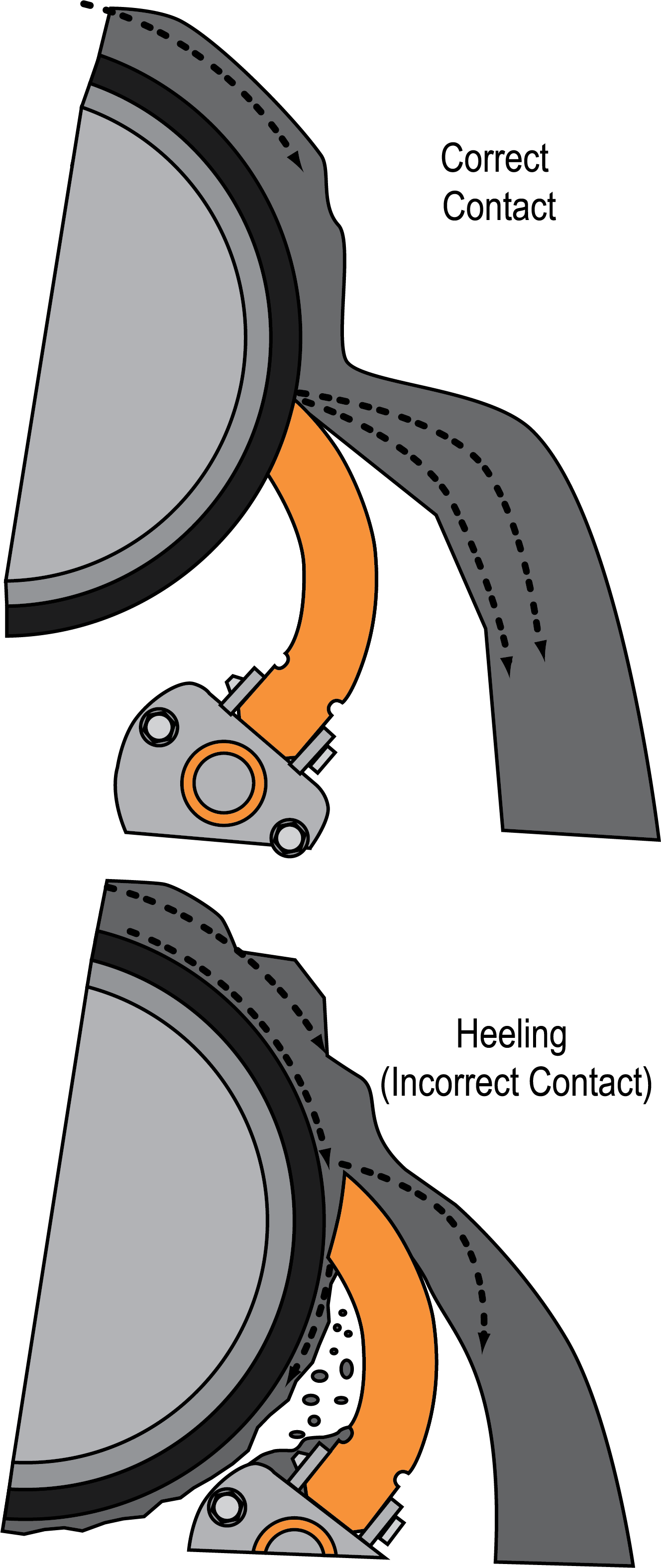

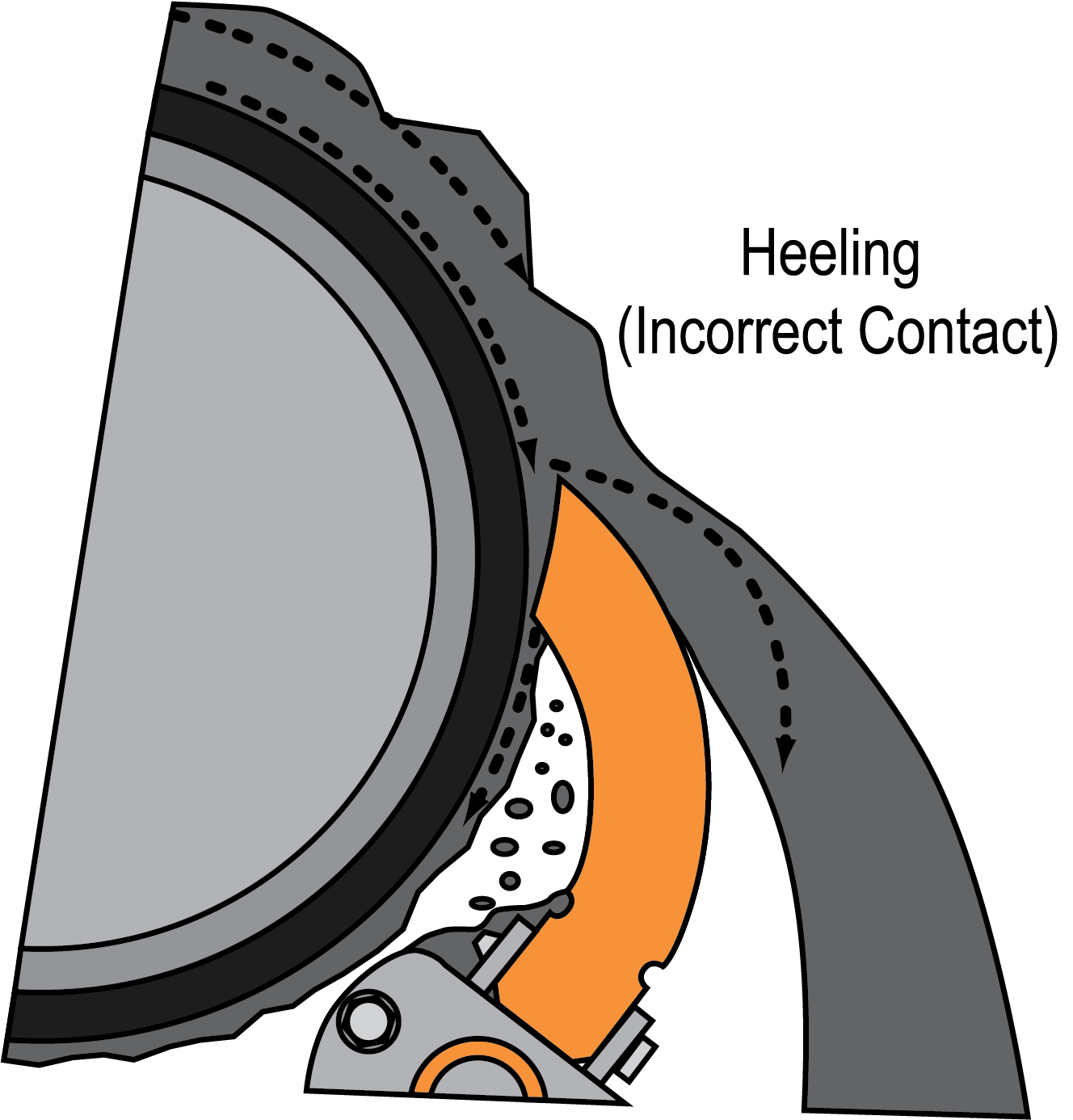

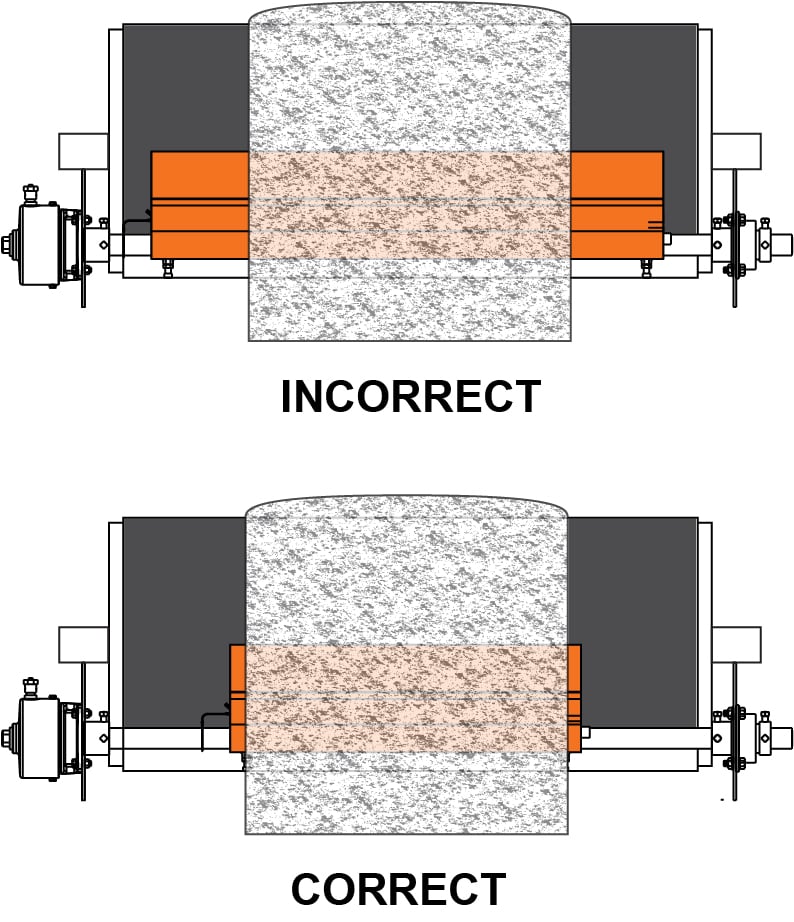

Pre-Cleaner “Heeling”

Pre-cleaners are designed to have the tip of the blade contact the belt first. As the tip wears, the primary cleaner normally rotates into the belt to maintain contact between the blade and the belt. However, problems can arise when an elastomer pre-cleaner blade is mounted too close to the belt. A primary cleaner installed in this manner, regardless of the blade’s design, will have the heel of the blade tip contact the belt first. This “heeling” creates a gap between the belt and the blade tip. Conveyed material collects in this gap and the accumulation forces the blade away from the belt. Once the blade is pushed away from the belt, larger amounts of material then pass between the belt and the blade, greatly increasing wear on the blade and belt and decreasing cleaning efficiency. The solution is to maintain the proper installation distance, so that the leading edge of the blade first contacts the belt.

See Also: Troubleshooting Belt Cleaner Installation Part 1.

Leave Comment