Where belt ends are joined with mechanical fasteners, the first requirement of a good joint is usually that the belt ends be cut square. Failure to do so will cause the belt’s splice area to run to one side of the structure at all points along the conveyor. This is usually seen as a quick side-to-side motion as the spliced area passes over any point on the structure. Using the belt edge as a squaring guide is not recommended, as the belt edge may not be straight. Used belting may have an indistinct edge due to wear, so one of the following procedures is recommended.

Because belt edges may not be square, cutting from an average centerline is preferred.

A. Centerline method

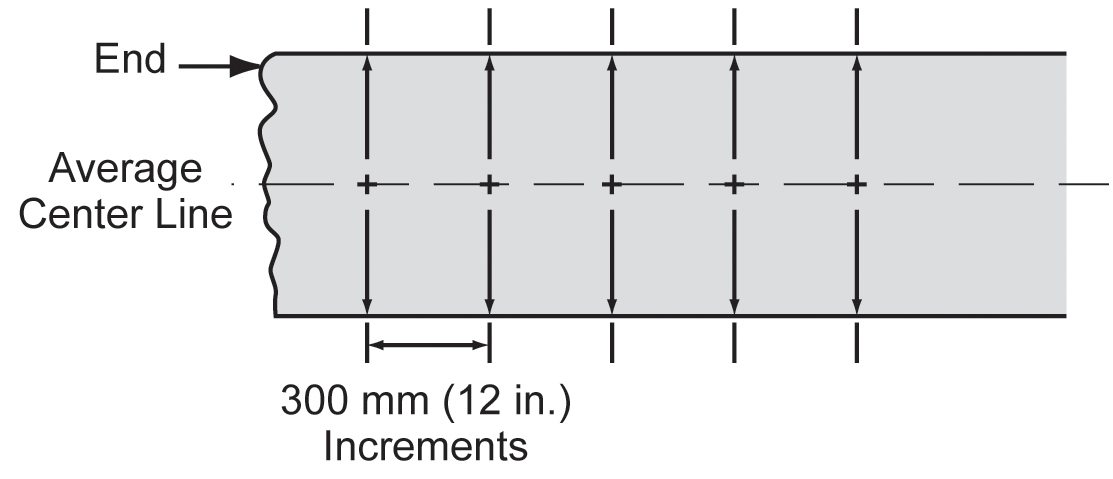

To find the belt’s average centerline, measure from one belt edge to the other at five points along the belt, each roughly 300 millimeters (12 in.) farther from the end of the belt. Mark a series of points at the center of the belt, and connect these points using a chalk line or ruler to determine the average centerline.

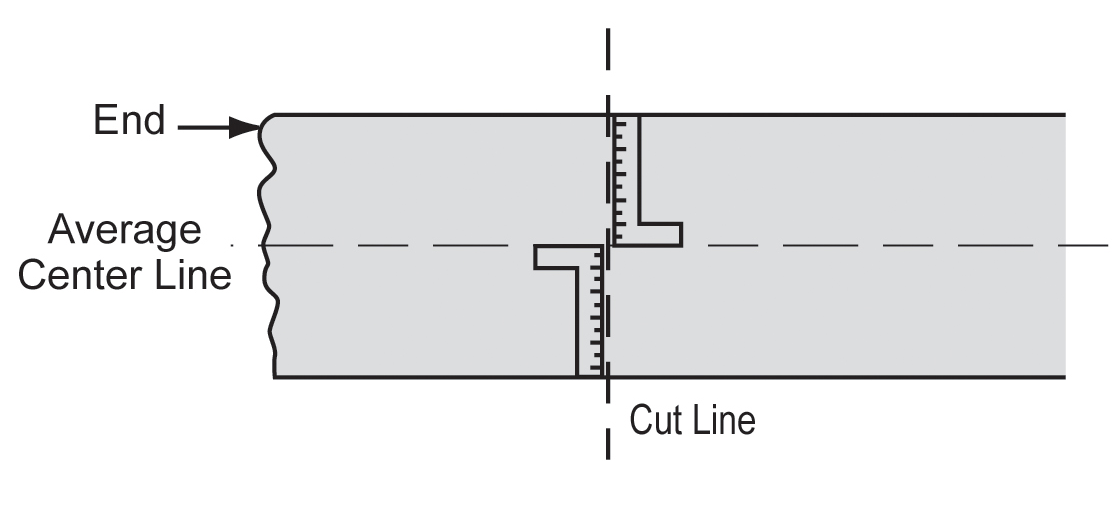

Draw the cut line by using a square. Draw a line across the belt perpendicular to the average centerline. This line can be used for the cut line.

B. Double-arc method

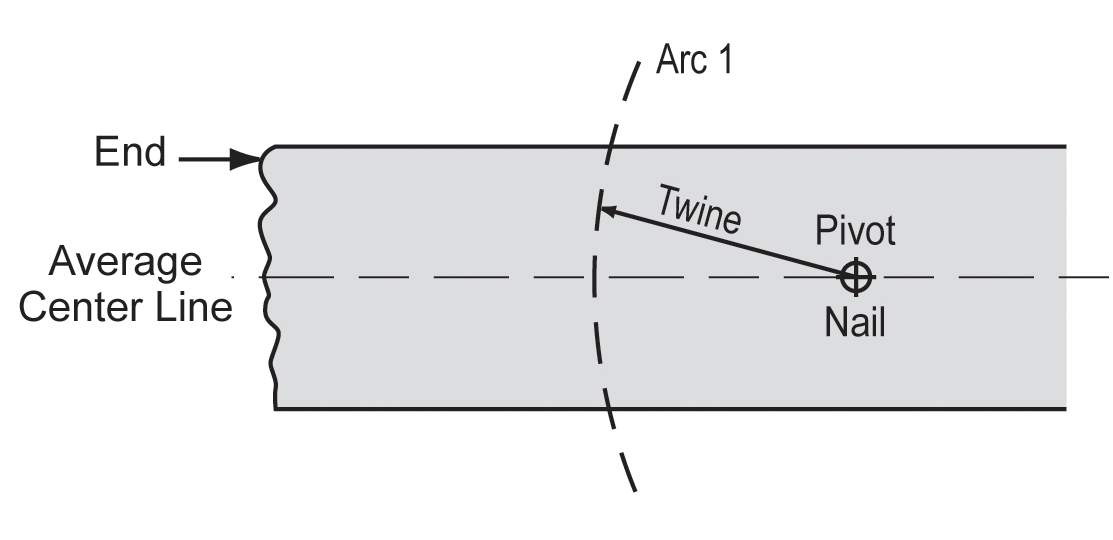

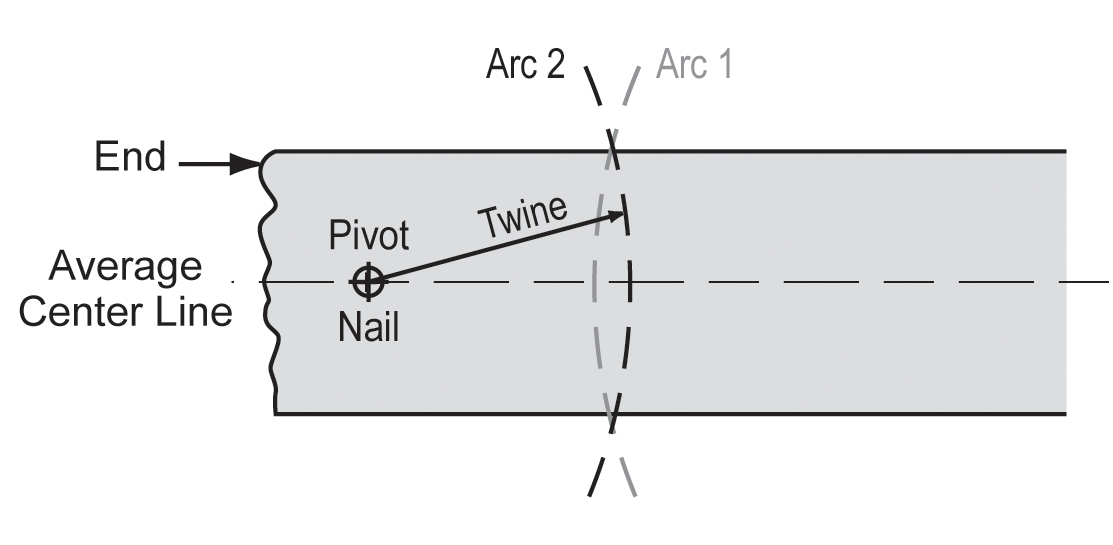

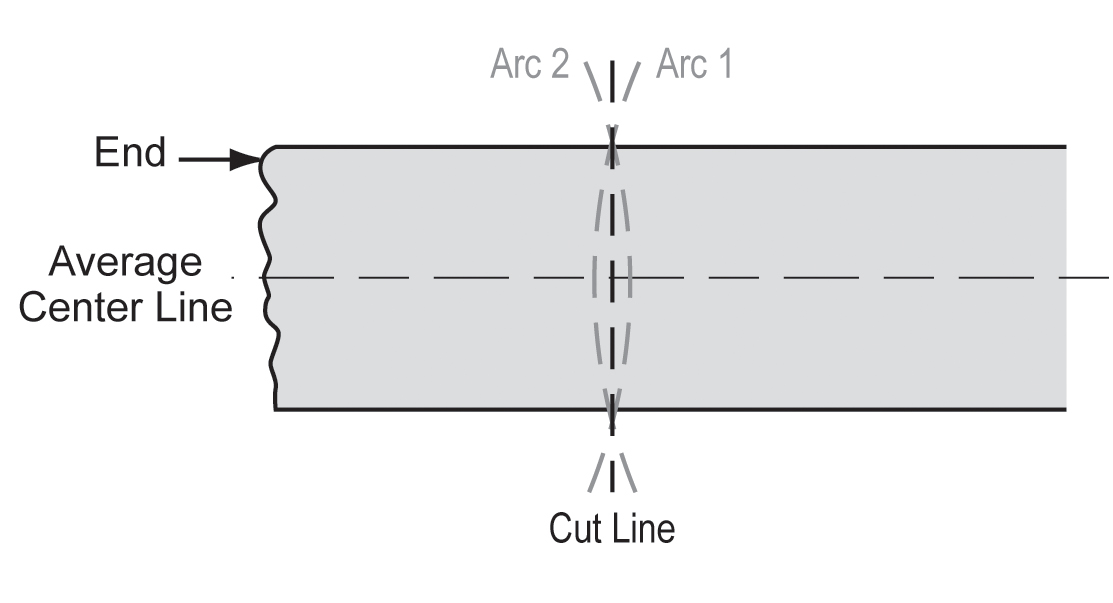

For greater accuracy, or on belts with worn edges, a "double intersecting arc" method can be employed. After establishing an average centerline as above, pick a point on the centerline two to three times the belt width from the belt end. Using a string with a nail on the centerline as a pivot point, draw an arc across the belt so the arc crosses the edge of the belt on both sides. Now, create a second pivot point on the centerline much closer to the belt end. Strike a second arc across the belt, this one facing the opposite direction, so the second arc crosses the first arc on both sides of the average centerline near the belt edges. Draw a line from the intersection of the arcs on one side of the belt to the intersection of the arcs on the other side. This new line is perpendicular to the centerline of the belt and becomes the cut or splice line.

Leave Comment