The primary cleaner, sometimes called the pre-cleaner or the doctor blade is installed on the face of the head pulley just below the trajectory of the material discharging from the belt. This position allows the material removed from the belt to fall in with the main cargo as it leaves the belt, minimizing any overloading of the dribble chute or other reclamation system.

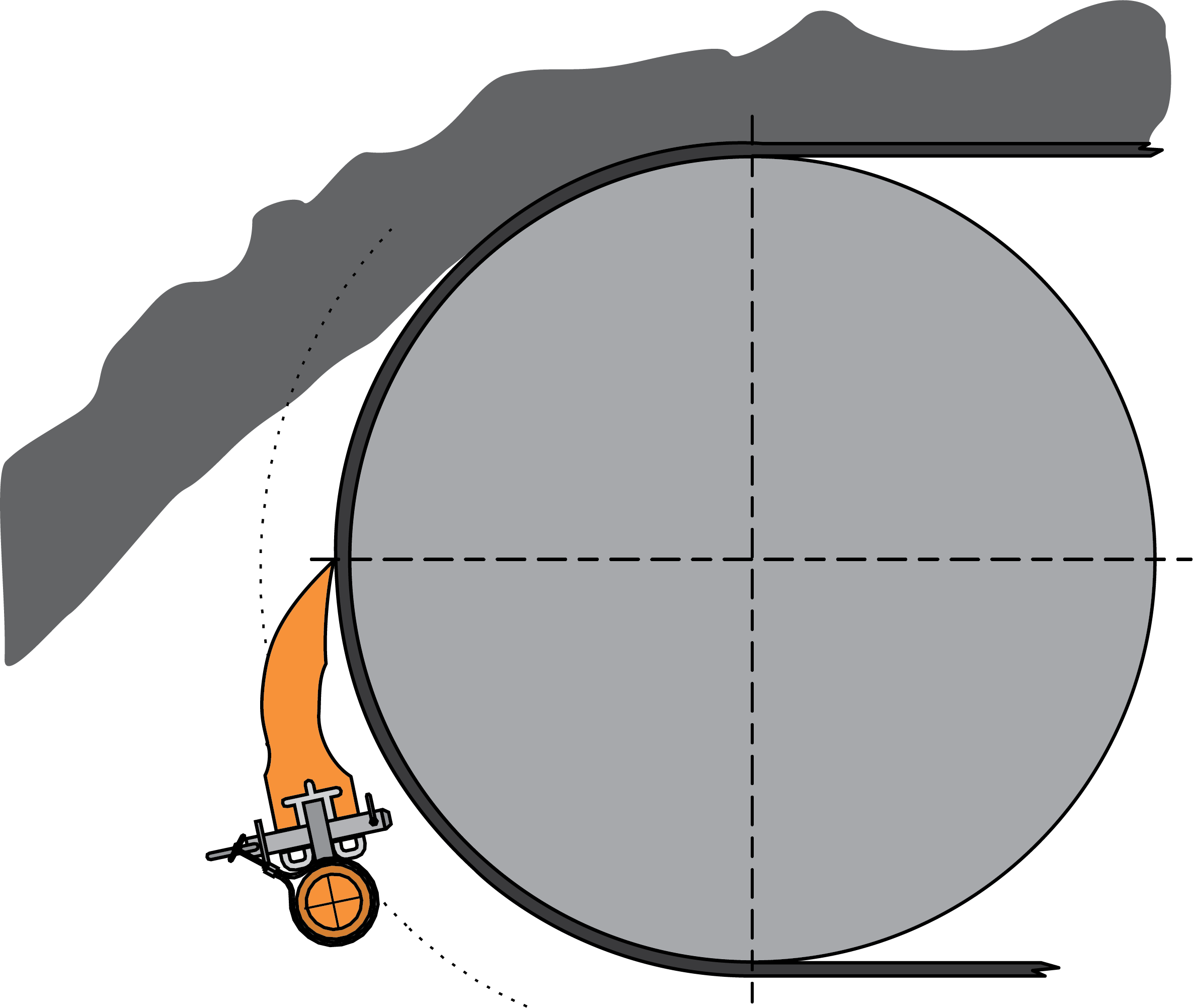

Pre-cleaners, with low blade pressure but an aggressive angle of attack, are installed to shear the coarse grit off the carryback layer. This clears away most of the carryback and enables the secondary cleaner to remove additional, underlying material. The primary-cleaner blade should be installed in a positive-rake position, inclined against the movement of the belt and pulley, typically at an angle between 30 to 45 degrees to a line tangent to the belt’s surface at the point of contact. Rather than blocking the path of the material, a pre-cleaner diverts the material away form the belt so it can return to the main material flow or move down the back of the cleaner into the discharge. Using this low angle of attack, in combination with elastomer pre-cleaner blades applied with light pressure against the belt, results in low wear rates for both the blade and the belt surface. If the angle of attack were greater (i.e., a zone-rake angle or negative rake position), more pressure would be required to hold the blade in position against the onslaught of material. Increasing the pressure increases the risk of damage to the belt.

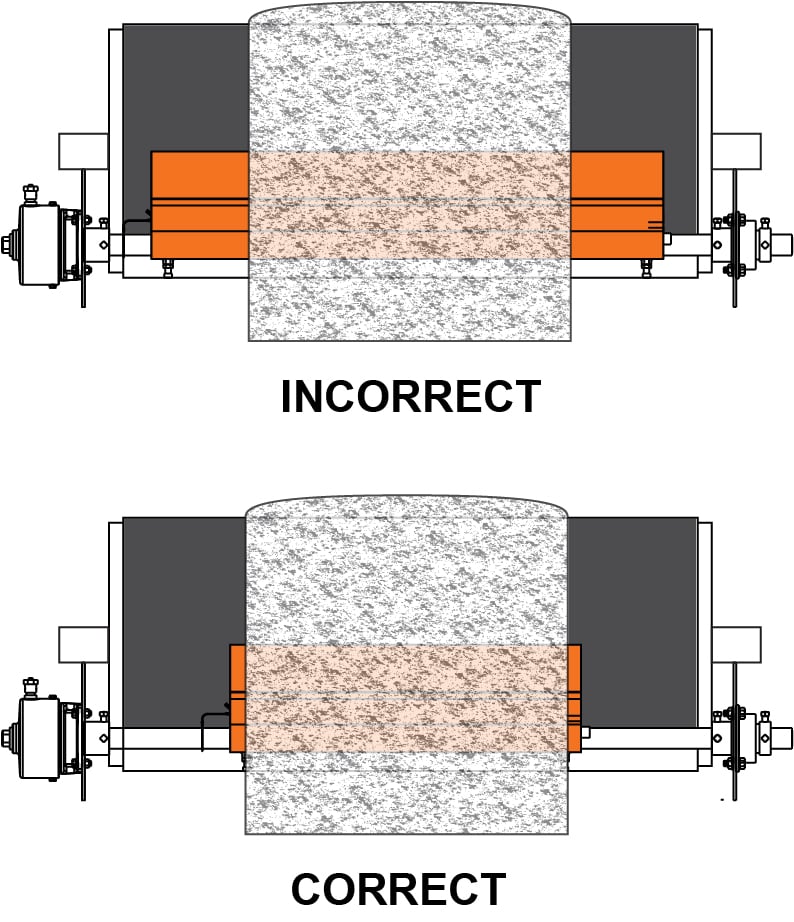

To minimize the risk to the belt, the splice, and the cleaner from even a lightly tensioned blade held in a positive-rake position, pre-cleaners usually use blades of resilient elastomer, such as urethane or rubber, rather than metal. A blade-to-belt pressure of approximately 14 kilopascals (2 lbf /in.2) combines cleaning performance with safety for the belt. This low blade-to-blade pressure means that the system will be able to relieve—that is, to bounce the blade away from the belt—when an obstruction such as a mechanical splice moves past the cleaning edge, thus reducing the risk of damage. Properly applied cleaning pressure improves blade-life and reduces belt wear. Too little pressure allows material to slide between the blade and the belt, where it can become trapped and impart wear on both. Too much pressure accelerates wear and increases energy required to move the belt.

There are a few key specifications to consider when choosing the appropriate belt cleaner for your belt conveyor.

In order to achieve an acceptable level of cleaning with only a single pre-cleaner (unsupported by any secondary or additional cleaners), it would typically be necessary to tension the blade against the belt with higher blade-to-belt pressure than should be recommended for the preservation of belt-life.

Leave Comment