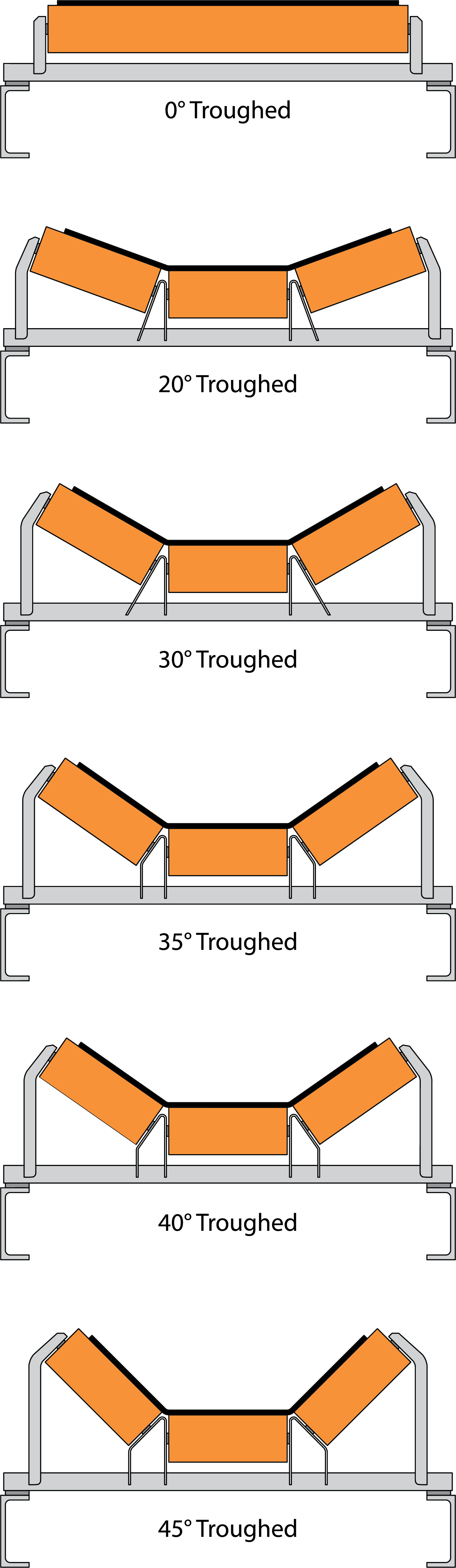

The standard trough angles in Europe are 20, 30, and 40 degrees; in North America, trough angles of 20, 35, and 45 degrees are common. However, with an ever-increasing global economy, one might find conveyors of any trough angle in any location around the world. At one time, the 20-degree trough was standard, but the deeper troughs have become more common as improvements in belt design and construction allow greater bending of belt edges without premature failure. In some special applications, such as high-tonnage mining, catenary idlers with a 60-degree trough are used to reduce spillage and impact damage.

Longer, higher speed conveyors may require the use of a thick belt, often with steel cords in the carcass. As a result, these belts may have less trough capability. Because of the lower bend requirements and the resulting reduction of stress in the belt, a 20-degree trough permits the use of the thickets belts, thereby allowing the heaviest materials and largest lumps to be carried.

Troughing angles steeper than 20 degrees are usually specified when the material has a low angle of repose. Higher troughing angles are suitable for a very broad range of applications. Higher trough angles work best when allowances are made for constrains such as limitations in transition distance and the requirement for exposed edge distance for skirt sealing.

While they offer the benefit of greater capacity, troughed belts also present some limitations. An area that can present problems, if not properly considered during the conveyor design and belting specification process, is the longer transition distance required to prevent stress at the belt edges. Other disadvantages of the steeper trough angles include a greater vulnerability to the effect of wind and higher potential for damage to the belt.

Troughing the belt typically makes a positive contribution to belt tracking. Another benefit of a troughed belt includes improved ability to contain material as a result of reduced edge spillage and loss due to wind.

Generally speaking, the selection of the angle of trough to be used on any conveyor is in most cases determined by the requirement to use the least expensive, and hence the narrowest, belt possible to transport the required tonnage of material.

See Also: Conveyor Belts Flat and Troughed Part 1.

Leave Comment