Observation Requirements

Access systems, including doors and work platforms, should be installed to make it easy to reach and observe equipment. Flow problems within chutes may be more easily solved if the material path can be observed. The actual path of material within a chute cannot always be predicted, so observation is necessary to allow adjustment of diverters, gates and grizzly bars. Many transfer chutes have only one inspection door. This is usually installed near the head pulley, where it does not permit a view of the actual material path in the lower chute and skirted area, where problems often occur.

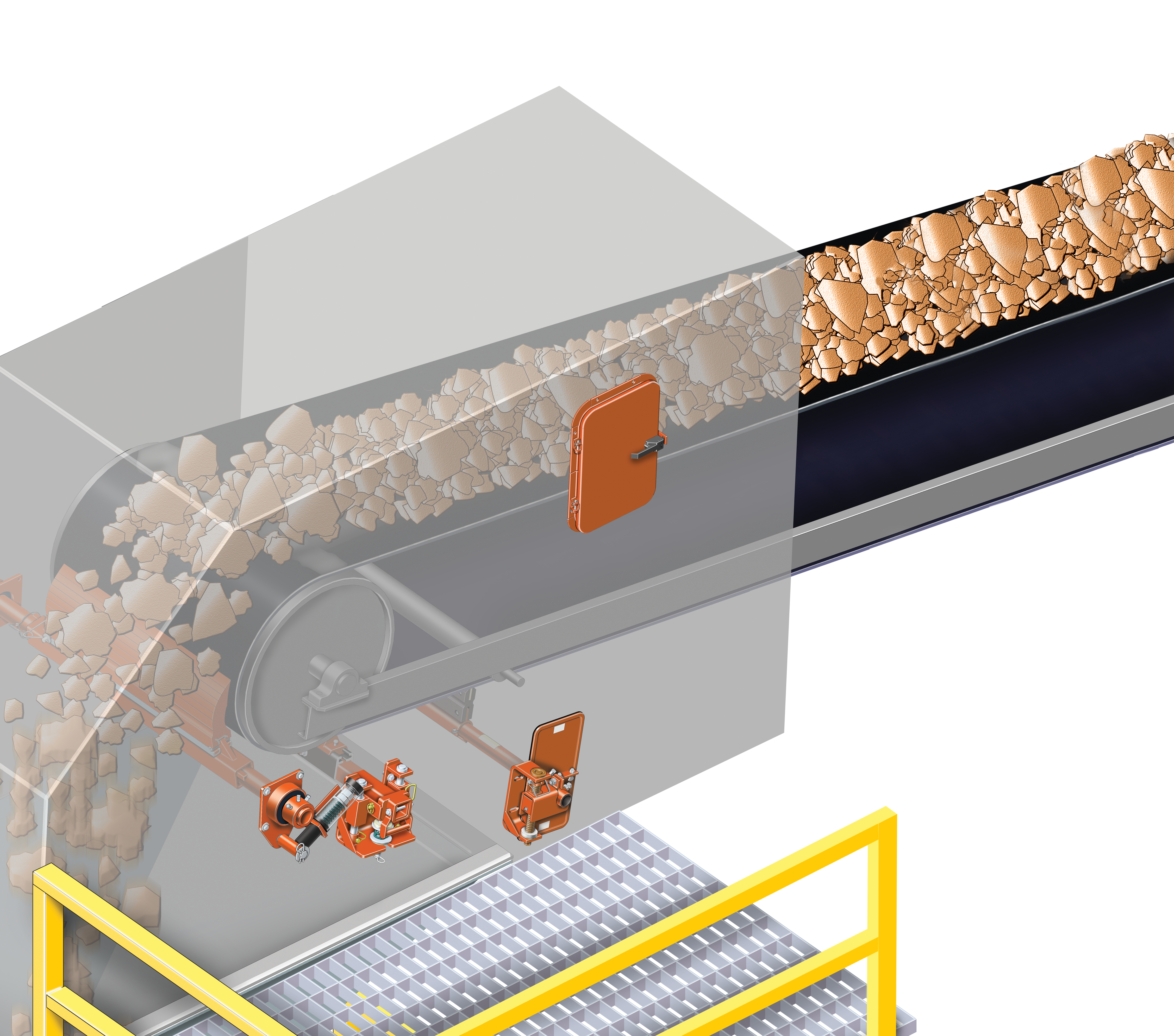

Flow problems within chutes may be more easily solved if the material path can be observed through an inspection door.

The chute should incorporate observation openings with easy-to-operate covers located away from the material path. These openings should allow safe observation of both the material flow and component wear at critical areas of the installation. The openings should be limited in size and/or protected with fixed bars or screens to prevent personnel from reaching in or material from flying out.

Consideration must also be given to providing ample lighting at access points. In some cases, overhead lighting is sufficient, but in other applications, it may be necessary to provide high-power spotlights or strobes that can be aimed into the chute to observe material movement. For general maintenance and machine repair, light of 540 to 1080 lux (50 to 100 foot-candles) is recommended. As many bulk materials absorb light, and due to the distance to the problem being observed, it is common for an installation to need lighting rated at 10 million lux (900000 foot-candles) to achieve this level of illumination.

Doors

Inspection doors should be side opening and sized so personnel can easily and safely view the components inside the structure. Doors must be installed on the non-wearing side(s) of the chute (that is, the side(s) away from the flow of impacting, or abrasive, material).

Doors should be designed for easy operation in tight clearances, with corrosion-resistant hinges and latching systems. It is important that all ports be dust-tight through use of a securely sealing door. Hinged metal doors with easy-opening latches are now available to provide access. Flexible rubber “snap-on” doors provide a dust-tight closure while allowing simple, no-tool opening and closing, even in locations with limited clearances.

Doors should be easy to close securely, once a service procedure is finished.

Door sizes should be large enough to provide the required access. If the observation and service requirements are limited to systems such as belt cleaners, a door that is 225 by 300 millimeters (9 by 12 inches) or 300 by 350 millimeters (12 by 14 inches) is usually sufficient. If service to major components, such as chute liners, will be necessary—or if personnel will need to use the door as an entry into the structure—then door sizes of 450 by 600 millimeters (18 by 24 inches), 600 by 600 millimeters (24 by 24 inches), or larger will be necessary.

Poorly-designed doors may have hinges and latches that are difficult to operate and, as a result, impede access. In addition, door seals unable to withstand abrasion and abuse from materials and implements used to reach through the doors become sources of dust. Some access doors also have small ledges or flat shelf areas, where combustibles such as coal might accumulate, creating risk of fire and explosion.

Leave Comment