How to Correctly Install Conveyor Belt Impact Cradles

Optimizing Impact Cradle Installation for Belt Conveyor Efficiency and Maintenance

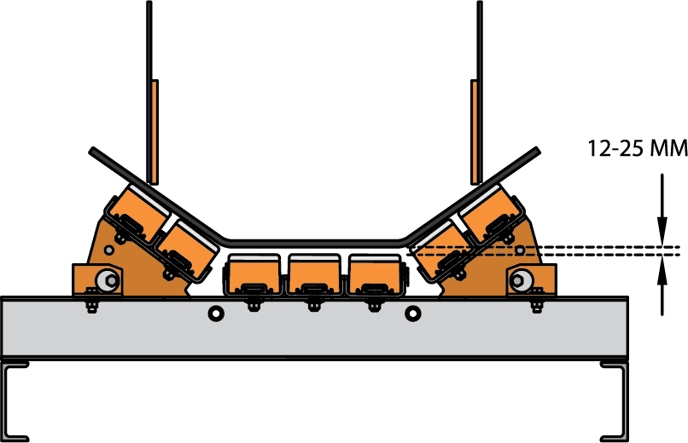

The impact cradle is typically installed with its central bars positioned slightly below the normal unloaded line of the belt, typically 12 to 25 millimeters (0.5 to 1 inch). This positioning enables the belt to absorb impact forces when materials deflect onto the cradle, minimizing continuous friction and wear on the bars.

The wing bars, located on the sides of the cradle, should align with the entry, exit, and intermediate idlers to prevent belt sagging and potential entrapment points. It's crucial that the bar directly beneath the steel chute or skirtboard wall align precisely with the wing idlers.

Cradles can be either welded or bolted to the stringers; bolting systems in place is often preferred as it facilitates easier maintenance. Some impact cradles come in a track-mounted design, simplifying installation and bar replacement as needed.

Adjustable wing supports streamline cradle installation, allowing the cradle to be initially positioned flat under the belt and then raised to the appropriate trough angle. The cradle design should incorporate simple adjustments for bar height and angle, accommodating idlers from various manufacturers and compensating for wear over time.