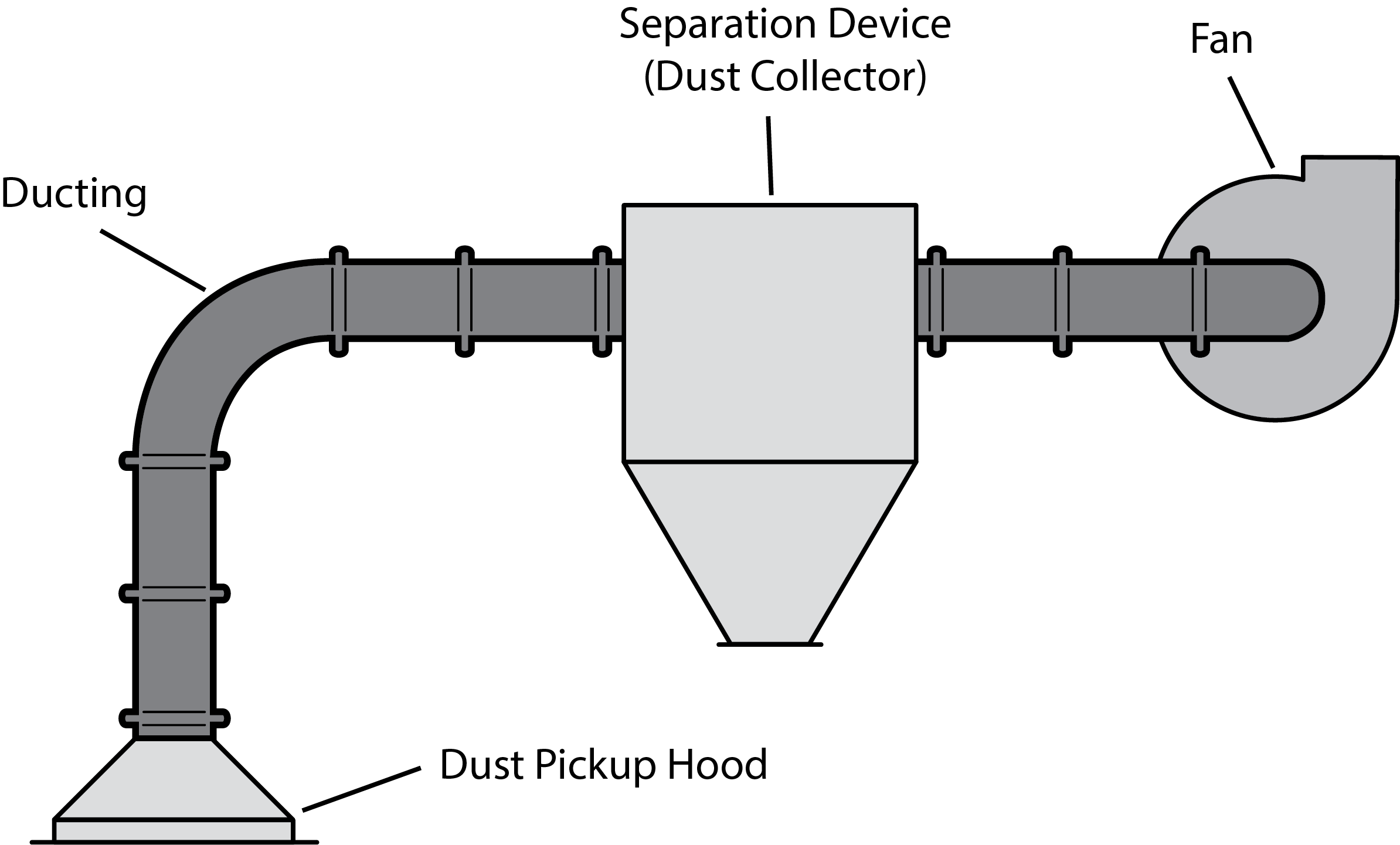

Mechanical dust collection systems are installed to pull dust bearing air away from a dust source, such as a conveyor loading zone, and separate the dust from the air and exhaust the cleaned air. A typical dust-collection system consists of four major components:

- Exhaust hood(s) or pickup(s) to capture airborne dust at the source(s).

- Ductwork to transport the captured air/dust mixture to a collector.

- Collector, filter, or separation device to remove dust from the air.

- Fan and motor to provide the necessary suction volume and energy.

Considerations for Dust Collection Systems

Dust collection systems vary widely in design, operation, effectiveness, space requirements, construction, and costs for operation and maintenance. The selection of a system should include a review of the following factors:

A. Dust concentrationIn bulk materials handling operations, the dust concentrations typically range from 230 to 23,000 milligrams per cubic meter (0.1 to 10.0 lbm/ft3) of dust, and the particle size can vary from 0.2 to 100 microns (μm is one millionth of a meter). The selection of a collector should be based on the level of cleanliness, or efficiency, required.

B. Characteristics of the air streamThe characteristics of the polluted (or dirty) air can have a significant impact on collector selection. Factors include temperature, moisture content, and relative humidity.

C. Characteristics of the dustThe properties of the dust itself are important to the choice of a dust collection system. Moderate to heavy concentrations of many dusts, such as silica sand or metal ores, can be abrasive, hygroscopic, or sticky in nature. The size and shape of particles will determine the applicability of fabric collectors; the combustible nature of many fine materials rules out the use of electrostatic precipitators.

D. Method of disposalThe method to dispose of collected dust will vary with the nature and amount of the material, the overall plant process, and type of collector used. Collectors can unload continuously or in batches.

Dry materials can create secondary dust problems during unloading and disposal. The disposal of wet slurry, or sludge, can be an additional materials handling problem for a wet collector. Sewer or water pollution problems can result if wastewater is not properly treated.

Leave Comment