In a conveyor system, where stability is a key to the control of fugitive material, any damage to the belt or pulley can adversely affect the system’s performance. By eliminating possible sources of damages to the conveyor, the entire system is improved and the risks of dust and spillage are drastically reduced.

The basic protection against this trapping of material between the belt and pulley is control of loading. The correct trajectory and drop height for material, along with the relationship between the speed of the loading material and the speed of the moving belt, are factors that help settle the load, reduce agitation, and minimize material spillage. Maintaining proper alignment of the belt is also required to reduce spillage that can drop material onto the return side of the belt.

An additional method available for preventing cargo from falling onto the belt return is to enclose or cover the return belt with decking. On long conveyors, this can turn into an expensive proposition; therefore, decking is rarely applied at locations other than near the loading zone. Even with decking applied to the full run of a conveyor, material could accumulate on top of the decking and eventually spill onto the return run of the conveyor, creating the need for a pulley-protection device.

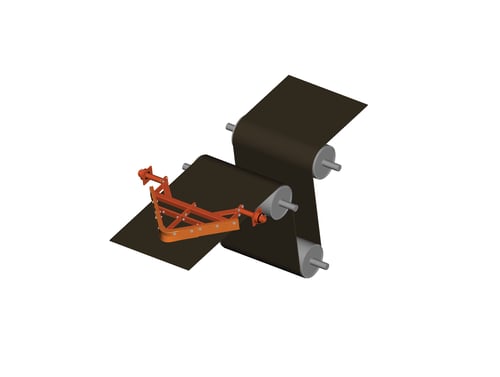

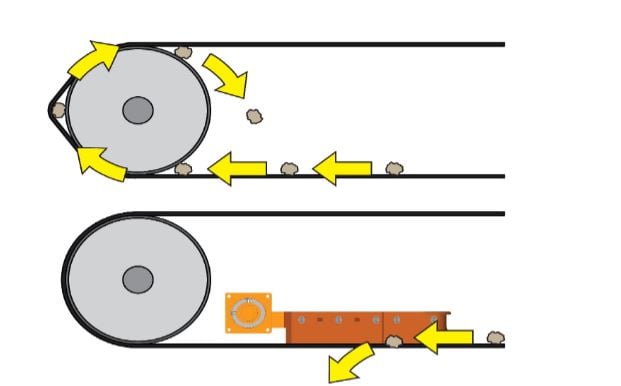

With ideal installations, and regardless of other precautions, there is still the possibility that lost components or conveyed material will spill onto the inside of the belt. Consequently, there is a need for a system to prevent these items from damaging the conveyor’s rolling components. These pulley-protection plows are most commonly installed at the tail pulley, but depending on the characteristics of the specific material and the individual conveyor, they may also be useful to protect the take-up or other pulleys.

This is a Job for a Plow

A pulley-protection plow removes fugitive materials with a simple, low-pressure scraping that directs the material off the belt much like a snowplow cleans a road. Instead of cleaning fines off the belt, the primary mission of a plow is to block any large lumps or stray conveyor components, such as idler rollers, belt-cleaner blades, or other tramp iron, from entering the tail pulley where they can damage the belt.

A plow that is installed slightly above the belt has the potential to capture a lump of material against the belt and, therefore, risks surface abrasion and damage with the possibility of ripping the belt. Pulley-protection plows are usually designed to float on the belt’s surface, using either the weight of the plow or a tensioning mechanism to hold the plow with a slight pressure, 13 to 20 kilopascals (2 to 3 lbf/in.2), against the belt. These plows are built of heavy-duty construction and tall enough to keep fast-moving materials from going over the top of the plow.

Pulley protection plows prevent material or foreign objects from entering the pulley where damage to the belt could occur.

More than Lumps?

If the belt carrying significant quantities of fines or slime on its inside surface, an additional step of providing a return belt cleaning system should be taken. At the expense of consuming additional conveyor drive power, this system would provide effective removal of material, reducing the risk of belt slip and material accumulation on the pulley.

A pulley-protection plow utilized for cleaning fines from the belt should be located in a position, such as right under the load point, to scrape the spillage off the belt and discharge the material where it can be easily collected. Care should be taken when discharging fugitive materials in the area of the tail pulley, as it can create a number of other problems, including material buildup below the conveyor. As with any belt cleaner, removed material that piles up under the conveyor can lead to premature wear of the belt top cover.

Leave Comment