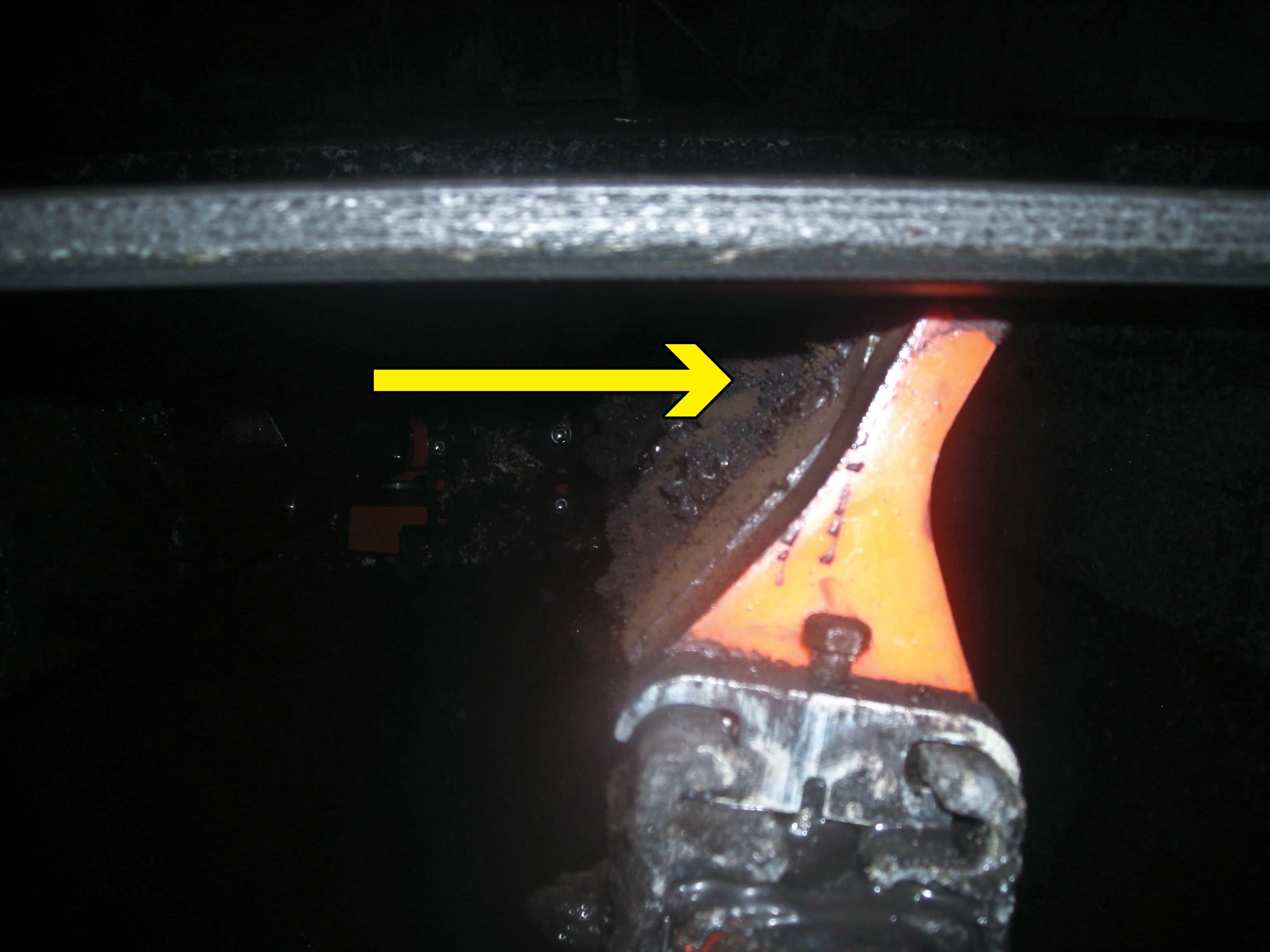

The angle of attack for the cleaning blades against the belt is a subject of importance. Generally speaking, there are two alternatives: positive-rake (or peeling) blades and negative-rake (or scraping) blades. With a positive rake, the blades are opposed to the direction of belt travel – with a negative rake cleaning angle, the blades are inclined in the direction of travel, typically at an angle of 3 to 15 degrees from the vertical depending on the type of splice. Blades installed in a position that is vertical, or perpendicular to the belt, at the point of installation are said to have a zero-rake angle.

Metal blades in a positive-rake position are quickly honed to razor sharpness by the moving belt and can cause expensive damage if they are knocked out of alignment. Positive-rake blades are occasionally subject to high-frequency vibration that causes the blades to “chatter,” repeatedly jabbing their sharpened edges into the belt cover.

Negative-rake blades allow material to build up on the inclined cleaning edge, which can force the blade away from effective cleaning contact; however, all belt cleaners, regardless of the angle of attack, are subject to buildup absent regular cleaning and service. With a negative-rake blade, the upstream edges of the cleaning blade will not bite into the belt surface, even if held against the belt with excess pressure.

A general opinion is that a positive rake is acceptable for primary cleaners, which are applied at very low pressures against the belt. However, it is advisable to use negative-rake blades in secondary and tertiary locations where higher blade-to-belt cleaning pressures and use of metal blades present more risk to the belt, splice, and cleaner itself.

Leave Comment